Sika AnchorFix®-2

Solvent and styrene free, epoxy acrylate based, 2-component anchoring adhesive.

- Fast curing

- Standard guns can be used

- High load capacity

- ETA to ETAG 001 for anchoring in concrete

- ETA to ETAG 001 for rebar connections

- ER to AC308 by IAPMO UES, anchoring in concrete for static, wind and earthquake loading

- Drinking Water certified

- Non-sag, even overhead

- Styrene-free

- Low odour

- Low wastage

- No transportation restrictions

Usage

As a fast curing anchoring adhesive for all grades of:- Rebars / reinforcing steel

- Threaded rods

- Bolts and special fastening systems

- Concrete

- Solid masonry

- Steel

- Hard natural stone*

- Solid rock*

Advantages

- Fast curing

- Standard guns can be used

- High load capacity

- ETA to ETAG 001 for anchoring in concrete

- ETA to ETAG 001 for rebar connections

- ER to AC308 by IAPMO UES, anchoring in concrete for static, wind and earthquake loading

- Drinking Water certified

- Non-sag, even overhead

- Styrene-free

- Low odour

- Low wastage

- No transportation restrictions

Packaging

| 300 ml standard cartridge | 12 cartridges per box pallet: 75 boxes |

| 550 ml standard cartridge | 12 cartridges per box pallet: 50 boxes |

Colour

| Component A | light green |

| Component B | black |

| Component A+B mixed | light grey |

Product Details

APPROVALS / CERTIFICATES

- Bonded injection type anchor according to ETAG 001 Part 1 and 5 Option 7, ETA-13/0968, Declaration of Performance 020403010020000001 5034408, certified by notified product certification body 1020, certificate of constancy of performance 1020-CPD-090-030091, and provided with the CE marking.

- Post installed rebar connection according to ETAG 001 Part 1 and 5 TR 023, ETA-15/0056, Declaration of Performance 020205010020000001 5034408, certified by notified product certification body 1020, certificate of constancy of performance 1020-CPR-090-033215, and provided with the CE marking

- Post-installed adhesive anchor in concrete elements according to ICC-ES Acceptance Criteria AC308, IAPMO UES Evaluation Report ER-0327

-

Fire resistance according to DIN EN 1363-1 (ISO 834), University of Brunswick, Report No. 3551/4926

- Fire resistance of Sika AnchorFix-2 injection systems in conjunction with concrete reinforcing bar and subjected to fire exposure, Centre Scientifique et Technique du Bâtiment (CSTB), REPORT No 26024178e

- Drinking Water Approval: Drinking Water System Components NSF/ANSI 61, Underwriters Laboratories (UL), MH49487

Shelf life

15 months from date of production

All Sika AnchorFix®-2 cartridges have the expiry date printed on the label.

Storage conditions

Stored properly in original, unopened, sealed and undamaged packaging in dry conditions at temperatures between +5 °C and +25 °C. Protect from direct sunlight.

Density

| Component A | ~1.62–1.70 kg/l |

| Component B | ~1.44–1.50 kg/l |

| Component A+B mixed | ~1.60–1.68 kg/l |

Compressive Strength

~68 N/mm2 (7 days, +20 °C) | (ASTM D 695) |

Modulus of Elasticity in Compression

| ~3 700 N/mm2 (7 days, +20 °C) | (ASTM D 695) |

Tensile Strength in Flexure

~24 N/mm2 (7 days, +20 °C) | (ASTM D 790) |

Tensile Strength

~13 N/mm2 (7 days, +20 °C) | (ASTM D 638) |

Service Temperature

| long term | -40° C min. / +50 °C max. |

| short term (1–2 hours) | +80 °C |

Application

Mixing Ratio

Component A : component B = 10 : 1 by volume

Layer Thickness

~5 mm max.

Sag Flow

Non-sag, even overhead

Product Temperature

Sika AnchorFix®-2 must be at a temperature of between +5 °C and +20 °C for application.

Ambient Air Temperature

-5 °C min. / +35 °C max.

Dew Point

Beware of condensation.Substrate temperature during application must be at least 3 °C above dew point.

Substrate Temperature

–5 °C min. / +35 °C max.

Curing Time

| Temperature | Open time - Tgel | Curing time - Tcur |

| +20 °C – +35 °C | 1 minute | 40 minutes |

| +10 °C – +20 °C | 4 minutes | 70 minutes |

| +5 °C – +10 °C | 8 minutes | 100 minutes |

| 0 °C – +5 °C | —* | 180 minutes |

| –5 °C – 0 °C | —* | 24 hours |

* Minimum cartridge temperature: +5 °C

SUBSTRATE QUALITY

Mortar and concrete must be older than 28 days. Substrate strength (concrete, masonry, natural stone) must be verified. Pull-out tests must be carried out if the substrate strength is unknown. The anchor hole must always be clean, dry, free from oil and grease etc. Loose particles must be removed from the holes.Threaded rods and rebars have to be cleaned thoroughly from any oil, grease or any other substances and particles such as dirt etc.

MIXING

Getting the cartridge ready: 300 ml / 550 ml

|

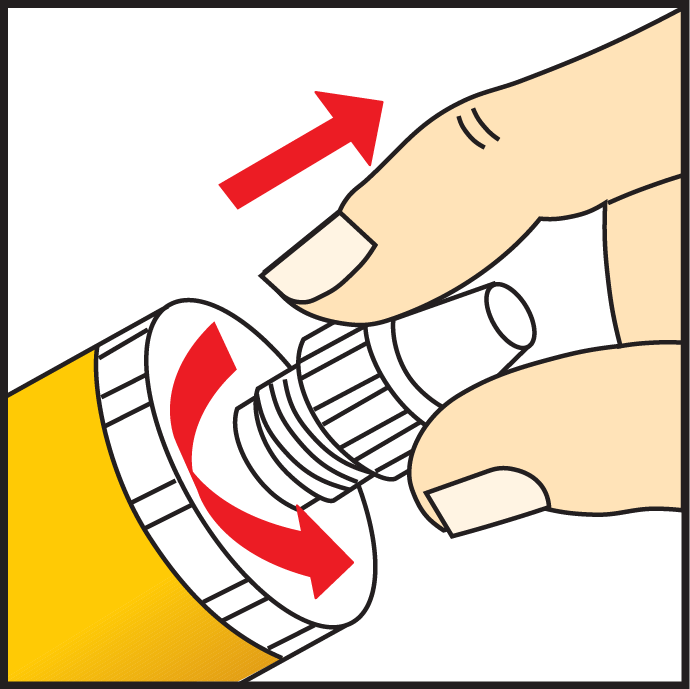

| 1. Unscrew the cap |

|

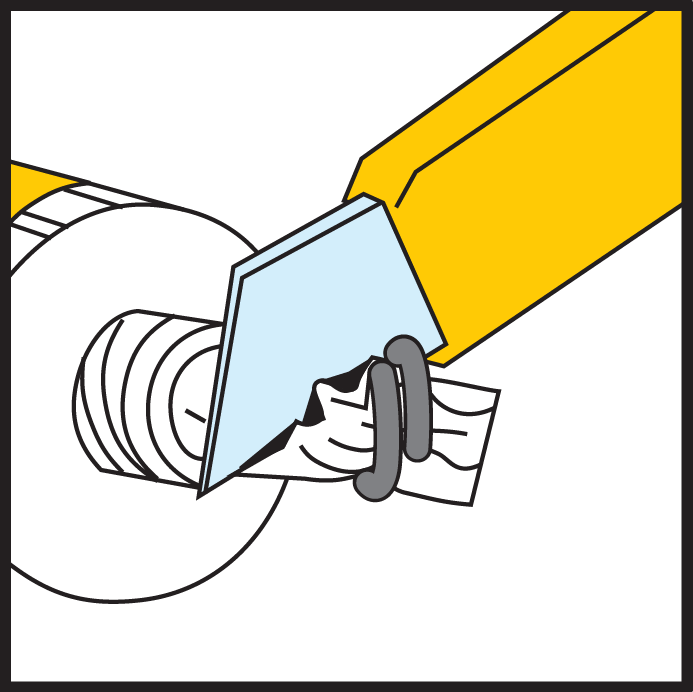

| 2. Cut the film |

|

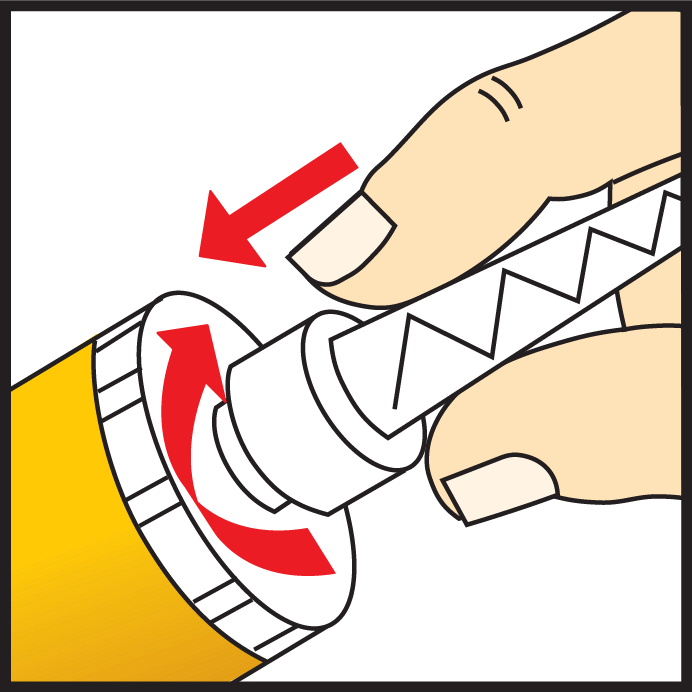

| 3. Screw on the static mixer |

|

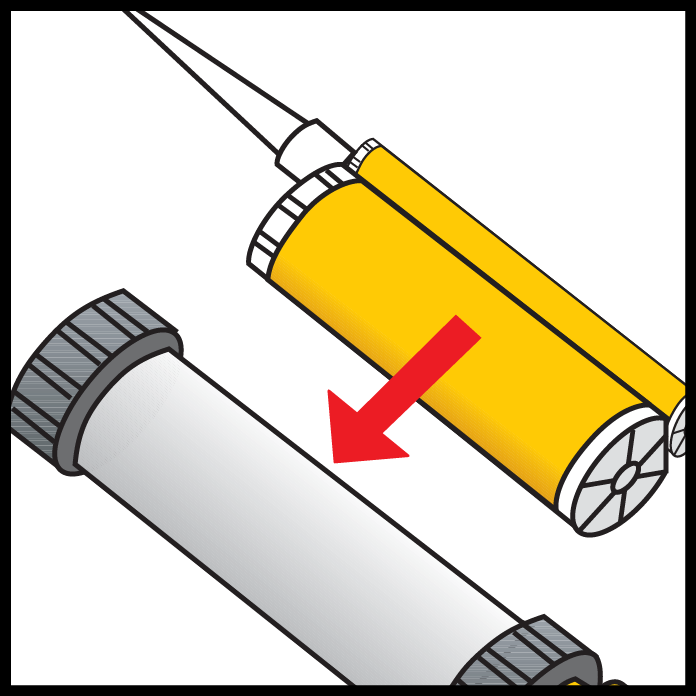

| 4. Place the cartridge into the gun and start application |

When the work is interrupted the static mixer can remain on the cartridge after the gun pressure has been relieved. If the resin has hardened in the nozzle when work is resumed, a new nozzle must be attached.

CLEANING OF EQUIPMENT

Clean all tools and application equipment with Sika® Colma Cleaner immediately after use. Hardened / cured material can only be mechanically removed.